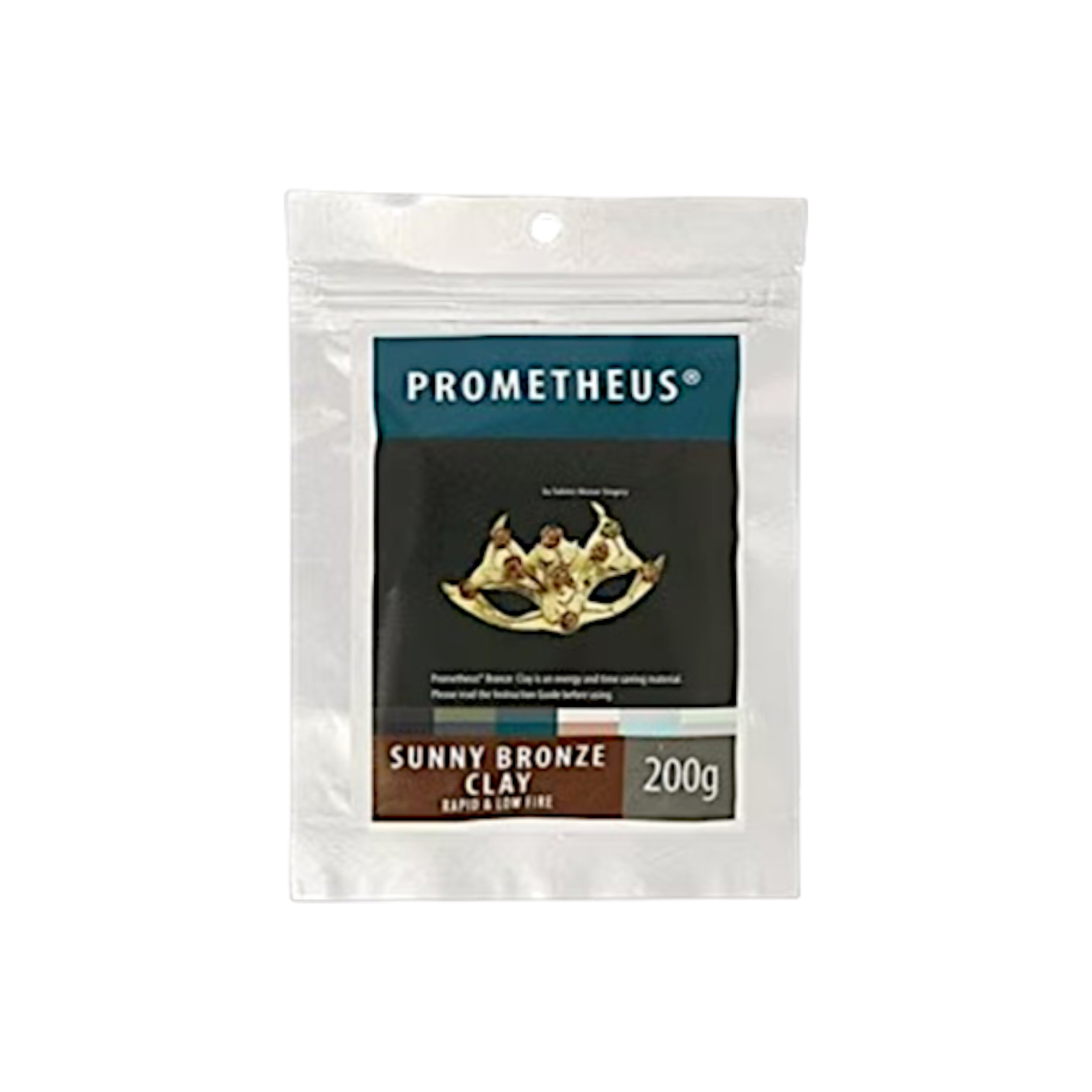

Bronze Clay Sunny Bronze Miscellaneous Contents Prometheus

€ 23,95 – € 42,50Price range: € 23,95 through € 42,50

Product number MCBC SB

Description

Make your own bronze jewelry with Prometheus Bronze Clay!

Bronze clay from Prometheus is a clay that turns into pure bronze when heated. It is a composition of bronze powder, water and an organic binder.

Like our other clays, it can be shaped by hand into sheets or tubes, in molds, textured and even used on a turntable.

It can be fired with most synthetic stones, Zirconia stones, pre-tested natural stones, glass beads and ceramic porcelain. Also, it is very suitable for enameling. It has a slow drying property so you can knead and shape the clay longer.

Prometheus Bronze Clay can be stored at room temperature and has a slow-drying property so you can knead and shape the clay longer. The clay has a shrinkage rate of 7-9%. Many properties are similar to silver clay; heating bronze clay takes place in an oven at 700°C for 30 minutes. Also, no stainless steel pan and/or activated carbon is required when heating. The package contains 100 grams of copper clay.

You use this clay to make shapes, by kneading, rolling out and rolling up.

Bronze clay is available in packs of 100 and 200 grams

Helpful tips when using Prometheus Bronze Clay:

– Bronze clay should be stored airtight, cool and dark.

In its container, bronze clay will keep for 1 year.

– Bronze clay can be diluted with distilled or boiled water.

– Always vacuum-pack leftover bronze clay immediately to prevent oxidation.

– Bronze clay dries by air and dries fairly quickly, so make sure everything is ready

in advance.

– Once dry, bronze clay is as hard as plaster, so it is possible to scratch or file patterns

into it.

– If it is dry and it breaks, you can repair a piece of bronze clay jewelry with paste.

– It is important to note that the clay cannot withstand frost.

Want to get started with Prometheus Bronze Clay yourself?

Then we recommend that you first take a workshop with a certified Art Clay Silver

instructor. Here you will learn how to work properly with the bronze clay and apply the tools correctly. Moreover, it is incredibly fun!

Instructions Prometheus™ Bronze Clay

Forms

Remove the clay from its plastic wrapping and place it on a clean plastic work surface and/or Teflon sheet. Use your fingers, clay roller, spatulas, projection molds, hobby knives, toothpicks and other tools to shape it.

You can add texture to the clay with stamps, texture plates and other interesting textures.

With a normal consistency, the clay does not stick to the hands or work surface. However, we recommend using an anti-stick formula. A small amount of the anti-stick formula on a surface will make silver clay come off effortlessly and not stick. The liquid can be used as a spray or applied with a brush. When using profile plates or stamps, you will find that it makes the images much sharper and brighter, than without the use of oil or balms. The formula is not harmful to the clay, substrate or health and is also odorless and fast drying.

To prevent the clay from drying out, it is advisable not to work on forming for too long. However, you don’t have to rush because Prometheus bronze clay gives you plenty of time. Should cracks develop nevertheless, you can work them away by adding water directly with, for example, a brush or a spray. Larger cracks or fractures can be repaired with a little paste.

Making pasta

To make pasta, mix a little clay with water until it has the consistency of lumpy yogurt.

Drying

Baking

Heating bronze clay can be done in an oven at 820 °C for 30 minutes. No stainless steel container with activated carbon is required when heating. However, some people do prefer this method because the synthering is better and subsequent pickling is not necessary.

A nice alternative is to heat the clay with a gas burner.

The possibilities of firing Prometheus Bronze clay:

As each oven is slightly different, we recommend you do some experiments, and keep a detailed oven log, to create your own specific firing table (**). You can fire at higher temperatures, but this would give you a higher shrinkage.

(*) Use gloves, pliers, paddle and safety glasses when loading and unloading furnace. Place hot pieces on a heat-resistant surface.

(**) Test your kiln’s accuracy by firing a small piece of clay. Electric kilns are allowed slight deviations, due to their temperature control systems and insulations. According to your test results, you can increase the firing temperature up to 5%.

(*) There is a demonstration video at www.proclays.com

(**) Burn your pieces in a well-ventilated place. Persons with lung or respiratory problems may be affected by the smoke created.

(***) Use gloves when working with ceramic blanket, inhalation It is dust, and wash hands after working.

When the firing is complete, take the package, put it on a heat-resistant surface and wait until it has cooled before unwrapping or take it out of the package while it is hot and quinch in water. Most of the fire scale leaves the piece. To get rid of the rest, leave it in hot pickling solution for some time.

Conventional Method

Place the dried piece (or pieces) on a stainless steel mesh and preheat at 800 deg.C/1472 deg.F. (**) Wait for the oven to increase again for its desired temperature, then begin timing your baking for 30 minutes.

When the firing is complete, take the piece, put it on a heat-resistant surface and wait for it to cool down or much better, quinch in the water while it is hot. (***) Most of the fire scale leaves the piece. To get rid of the rest, leave it in hot pickling solution for some time.

(*) This method is especially recommended for large pieces; statuetts etc.

(**) Most ovens are cooler near the front door, so put them close to the back of the drying oven.

(***) Be aware of water vapor.

Carbon Method

This is a 2-step method.

Step.1

Place the dried piece (or pieces) on a stainless steel mesh and put it in the pre-oven at 500 degrees C / 932 deg.F, or on a stove. Burn it for 10 minutes, take it on a fireproof surface and let it cool.

Step.2

Put about 3 cm. of activated carbon on the bottom of a steel container. Place the pieces with at least 1.5 cm space between each other and fill the container with activated carbon, close it and put it in the preheated oven to 800 ° C / 1472 ° C. Let the oven re-order to the target temperature and fire it for 90 minutes. When the firing is complete, either let it cool in the oven, or take it out and leave it on a heat-insulated surface until it is cold enough to take your pieces out. Another firing table is 800 ° C / ° F 1472 for 2 hours, which is better when PBC™ is combined with PCC™.

With a gas burner

Bronze clays suitable for torch firing are:

Art Clay Bronze,

Prometheus regular bronze clay

Promethens Sunny bronze.

The other varieties can only be baked in a special oven

Finish

Brush your piece with a metal brush and, if necessary, put it in hot pickling solution. (*) After staining, rinse the piece with water and dry. This will give you a nice warm reddish bronze color. You can also use many different patina solutions to give you other colors.

(*) We recommend Picklean™ granules. Mix a tablespoon of Picklean™ to a glass of hot water and leave your piece in it for some time.

Polish the piece with a polishing tool, polishing papers, a thumbler polishing or motor. Using polishing tools can give extra shine to your work.