Silver clay – Art Clay Silver

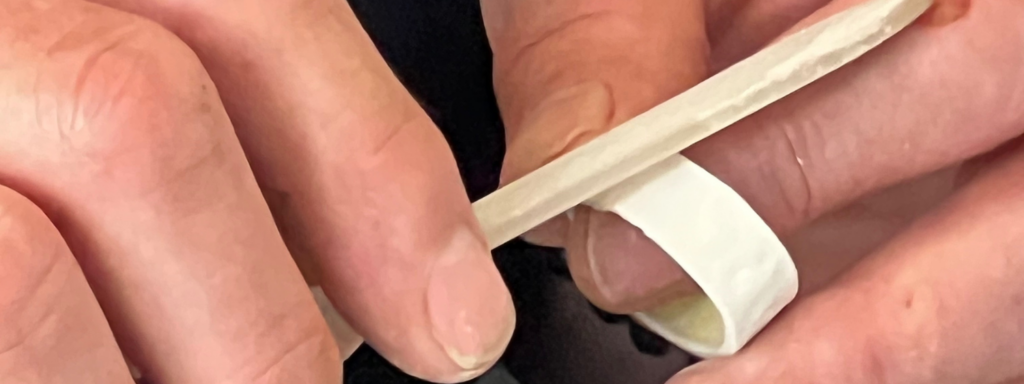

Silver clay consists of microscopic particles of silver, organic binder and water. The water evaporates during drying and the organic binder decays during firing, leaving 99.9% silver.

Silver clay feels like “regular” clay and can also be processed in the same way. Only the way of firing is different. This can be done in three ways: in a (ceramic) oven (from 650 °C), with a burner or on the gas stove.

Silver clay is made from recycled silver from circuit boards, computer hard drives, eyeglasses, jewelry, etc.

Art Clay Silver 999 Regular silver clay.

You use this clay to make shapes that you can knead, roll out and roll up. Working with silver clay 650 has the following advantages:

-

It can be baked at low temperature, with a hand gas burner or even on the gas stove. A special oven is not needed.

-

First grade silver haberdashery can be baked with it.

-

It shrinks only 8 to 9%.

-

It is the best kind to use along with glass and even some gemstones.

Before using, knead the clay briefly to push out any air bubbles. You can also do this in plastic wrap to prevent drying out.

Making your own silver jewelry at home with Art Clay Silver, Silver Clay

On Youtube you will find numerous short videos explaining how to make jewelry with Art Clay Silver.

Beginners guide

Watch 15 series of basic jewelry making techniques with Art Clay silver. If you learn the steps with these videos, you can make many different styles of basic rings and pendants in many ways of finishing.

Regular Art Clay Silver / Silver Clay is available in packs of 7, 10, 20 or 50 grams.

Silver Clay Spray Paste

The material in the syringe has the same clay base, but is diluted in such a way that it is possible to squeeze it out of the syringe. This allows very thin or special shapes to be obtained.

There are three different nozzles you can put on the syringe.

Blue= thin | Green= medium | Gray = thick

The nozzles can also be trimmed to an even larger opening or in such a way that a deformed string comes out. Always put the syringe paste with nozzle in a bowl of water when not in use. This prevents the paste in the nozzle from drying out.

Spray paste can also be used to make repairs on unbaked and baked-on projects.

Silver clay paste in a jar

This is basically the same as silver clay, only it has more water added to it, making it spreadable. You can use it to:

– Two pieces of dry clay to attach together.

– Repair cracks.

– Apply directly to leaves or twigs, creating a perfect copy.

– Create a paste pattern on dry clay.

– Repair a broken piece of jewelry.

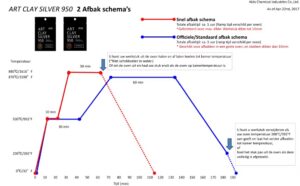

Silver Clay 950

Silver clay 950 Professional consists of 90% silver. This clay can only be baked in an oven.

The boulder is 60% harder than regular silver clay.

After firing, the piece can be hallmarked as 925 silver. ( purity 95% pure silver)

Because the clay is harder, a workpiece will be less likely to be damaged when worn. Therefore, this clay is ideally suited for professional manufacturing of rings, for making small fine rings, for open rings, spinner rings, bracelets etc.

The firing schedule differs from the firing schedule of Art Clay Silver 999.

Art Clay Silver 950 is great for making jewelry for sale or commission.

A unique piece of silver jewelry in 5 steps

1. Designing, shaping and modeling

Design and model your jewelry. Do take into account the shrinkage of the product, this is about 8 to 9%. Especially when making rings, this is of course very important.

2. Drying

When your design is finished then it must be dried properly. Drying can include air drying, using a hair dryer or on a hot plate. If the design is not properly dry it may spatter during heating. To make sure the workpiece is properly dry, you can do the mirror test. Place the hot workpiece on a mirror for a few moments. If no condensation is visible on the mirror when you lift the workpiece, it is properly dry.

3. Touching up, sanding and filing

The dried jewelry has hardened but is still fragile. You can touch up imperfections with Silver Clay paste or spray paste. Dry the workpiece again after applying the paste. Then you can sand the workpiece smooth with the sanding wipes. Baby wipes are also useful at this stage to achieve a perfectly smooth result. And at this stage, you can also file or scratch patterns or lines in the jewelry.

4. Heating

When the piece of jewelry is completely finished and all irregularities have been touched up, the piece is ready to be heated. Silver clay can be heated in three ways: 1 on the gas stove, 2 with a gas burner or 3 with a special clay oven. But there are limitations to heating with a gas burner or on the stove. So please read the baking instructions carefully first.

5. Polishing

After the jewelry is “baked” it can be polished. First remove the white layer with a polishing brush. If you want to keep the jewelry matte, leave it at that. For a high-gloss finish, use sanding cloths and the polishing needle. And finally, polish the jewelry with polishing paste.

Art Clay Products are safe to use.

Art Clay Silver is certified as an AP-approved product by ACMI (The Art and Creative Materials Institute, Inc.), an international association of approximately 200 manufacturers of art, craft and creative materials that seeks to promote the safety of art and creative products through a certification program.

In addition to silver clay, there are other types of Art Clay. More information about these other types can also be found in the knowledge base.

Art Clay Paper in various thicknesses

Art Clay Bronze

Art Clay Copper

Art Clay Gold

Art Clay Goldpaste

Art Clay Anti Tarnish

Art Clay Overlay paste