3. Touching up, sanding and filing

The dried jewelry has hardened but is still fragile. You can touch up imperfections with Bronze Clay paste. Dry the workpiece again after applying the paste. Then you can sand the workpiece smooth with the sanding wipes. Baby wipes are also useful at this stage to achieve a perfectly smooth result. And at this stage, you can also file or scratch patterns or lines in the jewelry.

Making paste from bronze clay. add a small amount of water to the soft clay and knead it carefully. Use this substance to fill any cracks or to attach several pieces together. You can also buy ready-made spray paste. This is also great for repairs and joining parts.

4. Heating

Notice! Method of heating White Bronze clay is different from regular Bronze clay and is described separately below!

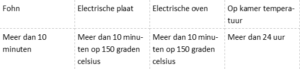

When the piece of jewelry is all neatly finished and all blemishes have been touched up, the piece is ready to be heated.

Bronze clay can be baked in 3 ways in a clay oven on an oven tray, by the activated carbon method and with a gas burner ( torch) We recommend the activated carbon method for best results.

Oven Plate

Make sure the oven is in a well-ventilated area. Preheat the oven to 820 degrees C. When the oven has reached the correct temperature, place the workpiece (preferably on a fiberboard to protect the bottom of your oven) in the oven. Close the door and wait for the kiln to reach the temperature of 820 degrees C again. You will fire for 30 minutes from that point.

When the firing is finished and your workpiece does not contain zirconia and the like, immerse the workpiece in cold water or let it cool to remove oxidation. While heating, observe safety guidelines.

Activated carbon method (our recommended method for best results)

Fill a stainless steel container with about 3 cm of activated carbon. Place the workpiece on top of the carbon. Leave the tray open. For multiple pieces, leave about 1.5 cm between pieces. Fire this for 10 minutes at 500 degrees Fahrenheit and then let it cool to room temperature.

Further fill the stainless steel tray with activated carbon so that the work pieces are in the activated carbon and seal it. Place it in a preheated oven (820 degrees C). Wait for the oven to return to temperature and then fire for 60 minutes. You can let the work pieces cool in the oven, or remove the stainless steel tray from the oven and let the pieces cool in the charcoal.

Baking with a gas torch (Torch) (not suitable for all types of bronze clay)

Place the workpiece on a non-flammable surface. Place the flame on the workpiece until it turns a homogeneous red color, then burn for 10 minutes (10 minutes of annealing) depending on the size of the workpiece. Be careful not to melt the piece. Then let it cool or dip it in cold water.

Caution! Heating White Bronze follows a different method.

This is done in 3 steps.

-

Place the dried workpiece on a stainless steel grid and place it in a preheated oven at 500°C/ 932°F, or on the gas stove. Fire it for 10 minutes, place it on a refractory surface and let it cool.

-

Put about 3 cm. Activated charcoal on the bottom of a stainless steel container. Place the workpiece on the charcoal, leaving at least 1.5 cm space between several workpieces, and fill the container with the activated charcoal . Put the lid on the container and place the container in a preheated oven at 770°C / 1420°F. Fire for 2 hours. When the firing process is finished, you can let it cool in the oven or remove the container from the oven and place it on a refractory surface until it has cooled enough to remove the work pieces from the charcoal.

-

You can combine White Bronze with Bronze Clay or Copper Clay and fire at the same time with the same firing schedule. Then keep in mind that the shrinkage of Copper Clay is 9-10%, White Bronze Clay 10 – 11% and Bronze Clay 13%.

Annealing (annealing):

To ensure that the workpiece obtains maximum strength and ductility, it is necessary to anneal the White Bronze Clay. Fire up your workpiece to 565oC (1050F) and keep it there for 5 minutes. Remove your workpiece from the kiln and throw it straight into cold water.