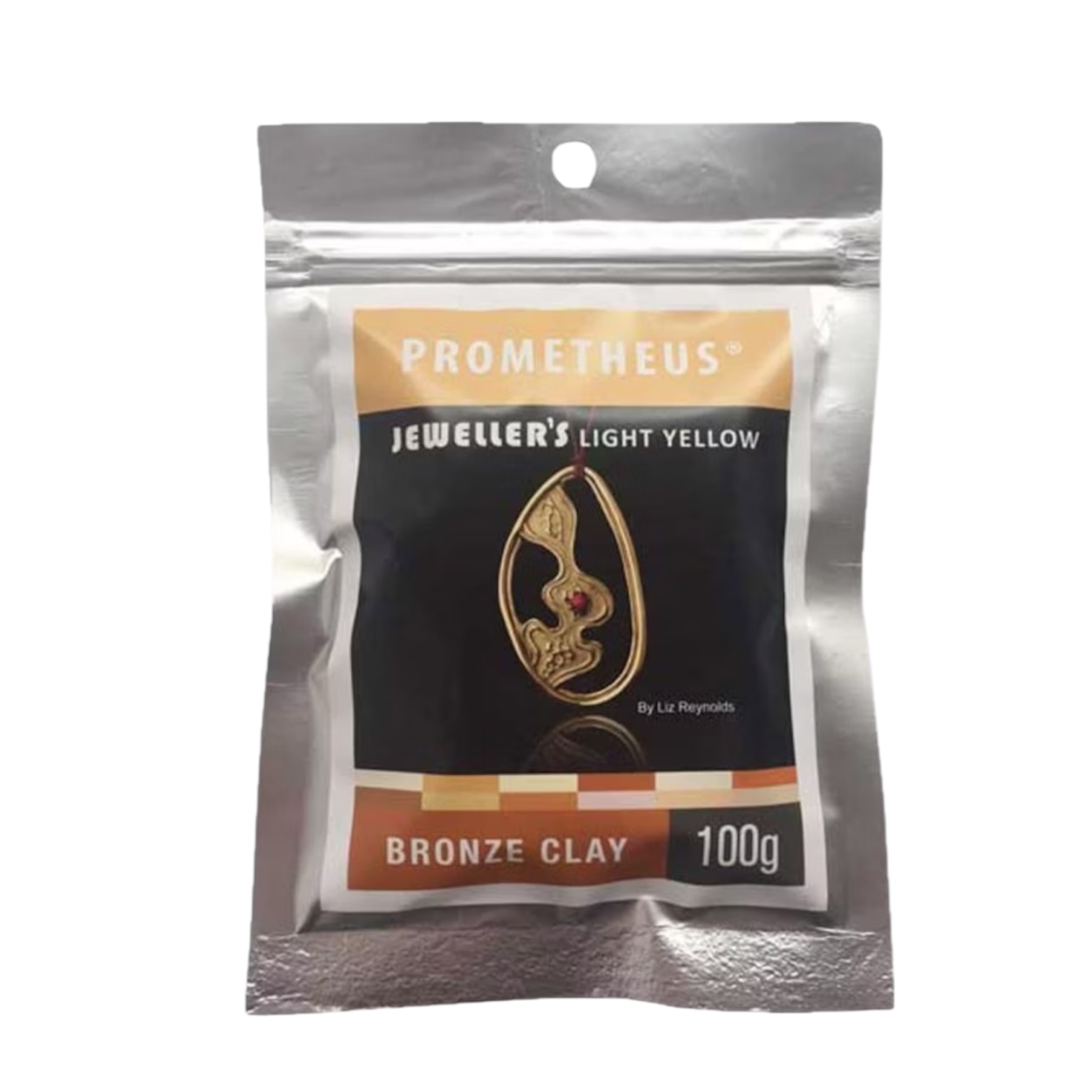

Bronze Clay Jeweller’s Light Yellow Bronze Prometheus Miscellaneous Contents

€ 24,95 – € 44,95Price range: € 24,95 through € 44,95

Product number MCBC LJB

Description

Make your own bronze jewelry with Prometheus Bronze Clay!

Prometheus® Jeweller’s Light Yellow Bronze Clay is a clay-like material that, after firing in a kiln, turns into pure, solid bronze.

It is composed of micron-fine bronze powder, water and an organic binder.

The clay can be worked in a variety of ways:

-

shaped by hand,

-

rolled out into a sheet or cord,

-

pressed into a mold,

-

provided with structure or texture,

-

or even turned on a potter’s wheel.

Prometheus® Jeweller’s Light Yellow Bronze Clay can be fired together with most

lab-produced gemstones (such as cubic zirconias), pre-controlled natural stones, glass beads, ceramics and porcelain.

During the firing process, the organic binder evaporates and burns off, leaving only solid bronze.

After firing, you can cast the workpiece:

-

brushing,

-

possibly pickling (to remove firescale),

-

and polish to the desired sheen.

Applications

With PLY® you can realize unique creations such as:

-

sieraden

-

ornaments

-

hollow objects

-

statues and sculptures

-

decorative works of art

Everything you make with Prometheus® Jeweller’s Light Yellow Bronze Clay is a work of art. Combine it with your imagination and let your hands do the work!

Baking process – two-step method (PLY®).

Step 1 – Combustion of the binder

-

Place the fully dried pieces on a stainless steel rack.

-

Turn on the oven cold (not preheated).

-

Increase the temperature to 500°C (932°F).

-

Baking time: 15 minutes.

-

Remove the pieces from the oven and place on a heat-resistant surface to cool.

💡 Purpose: To remove the organic binder to prepare the metal powder for sintering.

Step 2 – Sintering process (bronzing).

-

Apply a layer of about 3 cm of activated carbon to the bottom of a steel container.

-

Place the pieces in the container with at least 1.5 cm space between each piece.

-

Cover the pieces completely with activated carbon and seal the container tightly.

-

Place the container in a preheated oven at 780°C (1436°F).

-

Return the oven to the target temperature and bake for 1 hour.

-

After baking:

-

Option A: let the oven cool completely with the pieces in it, or

-

Option B: Carefully remove the container from the oven and let it cool on a heatproof surface until the pieces are cold enough to take out.

-

Post-processing

-

Brushing: remove loose residue or discoloration.

-

Pickling: use a pickle bath to remove any firescale.

-

Polishing: apply the desired finish – matte, satin or high gloss.

Summary of baking steps

| Step | Temperature | Time | Notes |

|---|---|---|---|

| 1. Binder combustion | 500°C | 15 min | Oven cold start, pieces on grid |

| 2. Sintering | 780°C | 1 hour | In activated carbon, closed steel container |